Project Description

Cleaning of Sheet Metals Coils

General

The cleaning of metal strips places particularly high demands on the quality of the products used. Only a completely cleaned surface guarantees problem-free coating or finishing in subsequent processes. Therefore, the typical impurities such as fats, oils, organic additives, metal dusts, oxides, and metal salts must be completely removed. We offer products for the cleaning and degreasing of all common materials and for every process type.

Materials

Our products have been continuously used for over 20 years in the cleaning of metal strips of steel, stainless steel, galvanized steel, aluminum, copper and brass. The experience gained in this process is part of the development of new products.

Processes

A wide range of methods is used in the cleaning of metal strips. Our products are optimized for spraying, dipping, brushing as well as for electrolytic and ultrasonic cleaning. For each process, there are a number of products that are optimally adapted to the respective operating parameters.

Determination of iron in aqueous solutions

Products

With the offered products we take into account all the requirements for the surface finish after cleaning. Furthermore, by adapting to the respective procedure we guarantee a uniform result and a stable process sequence.

- Acidic and alkaline products for a specified metal removal rate as well as neutral cleaners for a pickling-free cleaning.

- Products for low-foaming cleaning in all temperature ranges.

- Adaptation to the respective waste water and disposal technology.

- Complementary products for highly foaming saponification byproducts (defoamers) and heavy soiling (cleaning additives).

- Silica-containing products for hood annealing.

For a reliable before-and-after comparison, a precise determination of the surface cleanliness is necessary. Several quantitative methods are available for this purpose. With a thermochemical carbon analysis, organic components (oils, fats and metal soaps) are determined to 0.1 mg / m2. Inorganic components (metal dusts, silicates or inorganic salts) can be determined photometrically or by X-ray fluorescence.

Laboratory scale simulation of a cleaning process

Cleaning Process

After the laboratory phase, we perform the cleaning process in a pilot plant. Larger band sections are cleaned and the results are also evaluated.

Pilot plant for the simulation of cleaning processes

Product Development

The elaboration of methods for concentration determination completes product development. The methods usually comprise the determination of acid or alkalinity, salt and surfactant content. In addition, we support our customers with questions of bath care with simulations of ultrafiltration and investigations on the foaming of roller oils. The introduction of a new product is accompanied during the operational test phase by employees from the laboratory and the technical field service.

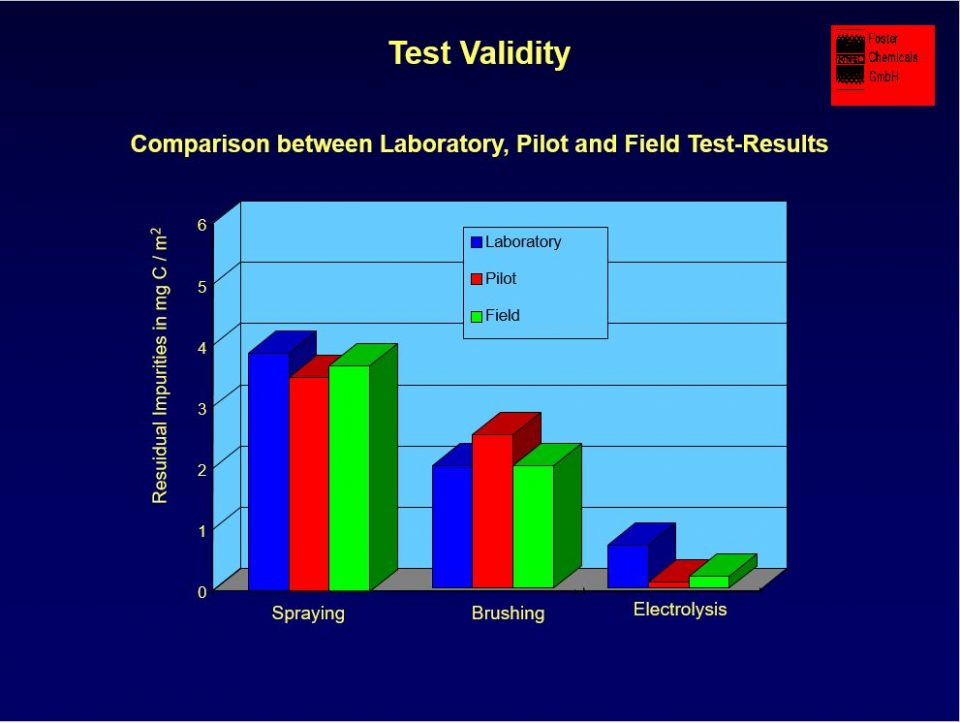

Comparison of results from laboratory, pilot plant and operational tests

Your Advantages

- No general purpose or standard products.

- Tailor made quality

- Decades of experience.

- Quick response when parameters are changed.

- Constant development of the products in terms of quality, cost, energy and work efficiency.

- Sophisticated analytical procedures for all questions.

Our Customers

Our customers include the world’s largest manufacturers of metal strips. We would be glad to provide you with the relevant reference customers on request.

Do You Have Questions?

Employees of the technical sales service clarify the characteristics of your equipment on site and take up the working parameters.

Make an appointment for a technically oriented presentation.