Project Description

Passivation of Metals

General

The pretreatment of metals before painting plays a key role regarding the paint adhesion and the longevity of the metal and the paint.

A nonexistant or a flawed conversion layer will quickly lead to corrosion underneath the paint and to loss of paint adhesion.

A proper pretreatment process on the other hand, will lead to an excellent paint adhesion and corrosion resistance, even with parts exposed to weather and the atmosphere for many years.

Foster Chemicals offers products for iron phosphating of steel, aluminium and zinc, certified products for chromium free conversion of aluminium, nano-passiviation and products for conversion of metal strip in a coil coating process.

Iron Phosphating

For a high quality iron phosphating of steel parts Foster Chemicals offersthe Ferrox Series products.

These products were developed for degreasing and phosphating in a single step and will generate phosphate layers with good paint adhesion and excellent corrosion resistance properties. In order to get a flawless conversion a final rinsing step with deionised water is necessary.

For simultaneous degreasing and phosphating of steel, zinc and aluminium products from the Alphos Zn Series can be applied.

Besides good phosphating properties Alphos Zn will provide additional corrosion restistance on aluminium.

Properties of Ferrox- and Alphos Zn Series:

degreasing and phosphating in one step

good paint adhesion on corrosion resistance

free of heavy metals and dangerous compounds

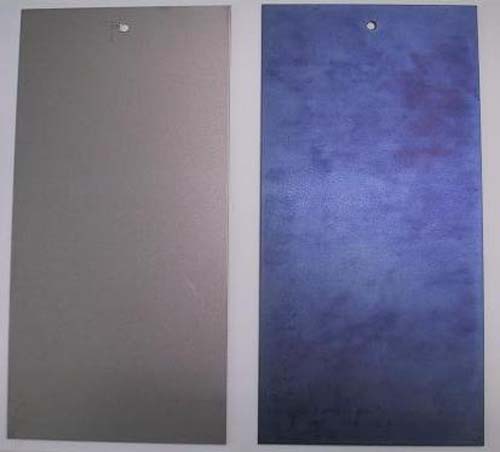

steel panels before and after iron phosphating

Chromium-free Conversion of Aluminium

For a long time hexavalent chromium was used as a standard product for conversion of aluminium before painting.

Because of new regulations passed by the European Community the use of hexavalent chromium compounds will be greatly limited. Due to a steady increasing enviromental awareness customers and consumers demand products free of carcinegenic and toxic substances.

For chromium free conversion of aluminium Foster Chemicals offers the product FAV 10.

FAV 10 was developed in order to replace hexavalent chromium and will yield comparable properties regarding paint adhesion and corrosion resistand on painted aluminium materials.

properties of FAV 10:

chromium free

acidic product

applicable in a non-rinse process

Nano-Ceramics Passiviation

For a high-quality passivation of steel, aluminum and zinc, Foster Chemicals offers products of the FAV 30 series. The conversion layers produced therewith are very thin with a layer thickness in the nanometer range. Due to their ceramic nature, these layers provide a very high corrosion resistance and good paint adhesion. The best results are achieved with a separate cleaning step. For small systems with only one active zone, the product is offered with as a combined cleaning and passivation. Products of the FAV 30 series produce resistant surfaces, are almost sludge-free and can be used at room temperature.

Conversion for Coil Coating

There is a steadily increasing demand for chromium free products for conversion of metals in coil coating applications.

The replacement products have to be comparable to chromate regarding not only paint adhesion and corrosion resistance but also the price level and the application procedure.

For conversion of metal strips before painting Foster Chemicals offers products from the FAV-Serie. These products are free of toxic compounds and can be applied by dipping, rinsing or by a chemcoater.

Normally the application of FAV products can be carried out in a non-rinse process.

Do You Have Questions?

Employees of the technical sales service clarify the characteristics of your equipment on site and take up the working parameters.

Make an appointment for a technically oriented presentation.