Project Description

Pickling and Treatment of Stainless Steel

General

The high corrosion resistance of stainless steels is achieved by the formation of a chemically resistant layer of chromium oxides. For outdoor use – particularly for offshore applications – as well as for contact with chemicals, this layer must uniformly and completely cover the entire metal surface.

In the production of stainless steel parts, the metal surface is greatly changed by thermal and mechanical machining. Oxide layers are formed on weld seams, dirt and foreign particles are incorporated into the material or deposited on the surface. The protective layer can not form in these areas and the stainless steel is prone to corrosion.

The interfering influences, however, can be removed very effectively and economically by a chemical mordant. Only on a stained surface can an optimal protective layer arise.

For the pickling of stainless steels, Foster Chemicals offers a wide range of products for all applications.

Pickling as Immersion Application

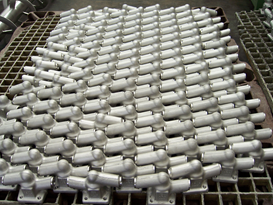

The pickling of stainless steels in dipping processes is suitable for small to medium sized parts. The parts are completely immersed in a bath made of a thin liquid pickling solution. The pickling takes place on the entire metal surface, both inside and outside. Pickling dipping processes are characterized by a low effort and easy handling.

Two product types are available for the immersion application. Products based on nitric acid are particularly fast and easy to use. Products based on sulfuric acid are safer, more productive and easier to dispose of.

All products are offered in concentrated form or as ready-for-use solutions.

Untreated stainless steel parts with discolouration by thermal treatment

After pickling – uniform, clean metal surface

Treatment with Spray-on Pickling Gels

Pickling gels are used in the treatment of large to very large parts, which can no longer be treated in a dipping plant. Stainless steel plants, which are to be treated only from the outside as well as those which can not be transported, are treated with pickling gels – on site.

These pickling products are applied by spraying. The gels are liquid and can be sprayed onto the surface of the parts to be treated. Due to their high viscosity, they adhere to the metal surface and thus produce the pickling effect.

In addition to a standard product for a wide range of materials, Foster Chemicals also offers spraying gels for special cases:

Sensitive materials – soft spraying gels

Products for hard-to-treat materials

Nitric oxide reduced spray gels

Spray gels with indicators

Colored pickling gels for optimum visibility of the surface coverage

Examples of application of picking gels

Pickling pastes – local treatment of welding seams

Pickling pastes are highly viscous, non-flowing pickling agents. They are mainly used for the cleaning of welding seams. The application is done with an acid-proof brush. The pickling paste is then removed. We offer a wide range of pickling pastes for all problems.

Pickling pastes are also available in 1 kg or 2 kg cans for optimal handling.

Weld seam in the initial state

Weld seam after pickling with a pickling paste

Electrolytic pickling and cleaning

Pickling products based on hydrofluoric acid require special care in handling and disposal.

Particularly when cleaning weld seams, pickling pastes can be replaced by electrolytes with a significantly lower risk potential. Weld seams are pickled quickly and reliably with the aid of electrical current and an acidic electrolyte. The products used are less dangerous and easier to dispose of.

The product range covers all fields of application:

- Standard electrolyte for cleaning and pickling. After treatment, a clean, dull surface is formed

- Polishing electrolyte – after application, a bright and shiny surface is produced

- Viscous electrolyte – for cleaning oblique surfaces and when working “overhead”

- Marking electrolyte – for the electrolytic labeling of stainless steel. Produces a highly-resistant, dark gray to black, non-abrasive surface

- Neutralizing agent – for neutralizing acid residues after pickling

After Treatment

After pickling, product residues as well as all reaction residues must be completely removed by rinsing with water. Residues of pickling agents can lead to corrosion or destruction of the pickled parts.

For fast and complete formation of the oxidic protective layer, pickled parts can be treated with a passivating agent.

Your advantages

- Long-term experience with all processes and materials

- On-site consultation

- Everything from one supplier – pickling products, equipment, accessories

Do You Have Questions?

Employees of the technical sales service clarify the characteristics of your equipment on site and take up the working parameters.

Make an appointment for a technically oriented presentation.